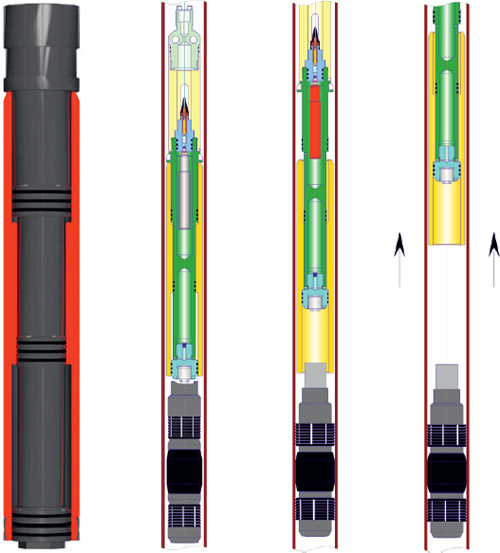

Explosive slips bridge plugs manufactured by LLC "Promperforator" consist of the plugging element (plug) and the reusable setting tool. Plugging element is manufactured versions:

- PVSh-PP.400 – are used for separation of productive formations. They are made of aluminum alloy with iron slips (table 1).

- TIREX-PP – are composite plugs used for installation of easy-to-drill isolation plugs (table 2). The plugs are сomponents FRACline® assembly set in Plug-and-Perf technology.

- PVSh-PP-C.400 – are cementing packers of special design used to inject cement slurry to under-packer and annular space during well maintenance. They are installed above the non-pressurized interval (table 3).

- VrP Series – reliable and cost-effective solution for installation of an easy-to-drill isolation bridge in wells where resistance to pressure drops more than 40 MPa is not required. This bridge type is more efficient replacement for VP-type aluminum packers (see Table 4).

Plugging elements are installed with the help of PVSh-PP.300 setting tools (Table 5) including ZPVSh-102PP propellant charges or IGP hydraulic setting tool. ZPVSh-102PP charge is initiated by PPT-230 ignition cartridge during wireline works. Ignition of ZPVSh-102PP charge generates gases for filling the setting tool cavity to move the shell along the stock of the setting tool, to cut pins (or shear pins in case of TIREX-PP) and to install the plug.

Specific Features

- Lowering and installation of the plug is possible in vertical, directional and horizontal wells on TCP, wireline and coil-tubing.

- The plug has three levels of protection against premature installation while running in hole.

- A special adapter for each plug type is supplied together with composite plugs.

- The setting tool is adapted for work with other composite and soluble plugs made in Russia and abroad.

- Operational life of the setting tool is increased to 5 shootings.

- A pattern for each plug type is supplied under a separate purchase-order.

- For installation of plugging elements with the help of IGP-76 or IGP-98 hydraulic setting tools it is sufficient to use the unit for pressure supply to the tubing (coil-tubing).

Table 1. PVSh-PP.400 Plug Technical Characteristics

| Parameter | Value | View | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PVSh- 82PP.400 | PVSh- 88PP.400 | PVSh- 92PP.400 | PVSh- 97PP.400 | PVSh- 102PP.400 | PVSh- 110PP.400 | PVSh- 118PP.400 | PVSh- 135PP.400 | PVSh- 138PP.400 | PVSh- 146PP.400 | ||

| Outside diameter, mm | 82 | 88 | 92 | 97 | 102 | 110 | 118 | 135 | 138 | 146 |  |

| Se ng tool name |

PVSh-82PP.300 IGP-76 |

PVSh-102PP.300 IGP-98 |

|||||||||

| Internal casing diameter, mm: | |||||||||||

| min | 88 | 94 | 98 | 104 | 109 | 117 | 125 | 144 | 146 | 154 | |

| max | 98 | 104 | 106 | 109 | 118 | 124 | 133 | 152 | 155 | 164 | |

| Max allowable hydrostatic pressure, MPa | 130 | ||||||||||

| Max allowable operating temperature, °C | 150 | ||||||||||

| Max allowable pressure difference between separated intervals, MPa | 70 | 50 | |||||||||

| Length, mm | 565 | 565 | 575 | 575 | 450 | 450 | 565/498* | 530/473,5* | 530 | 560 | |

| Weight, kg | 9,7 | 9,7 | 10,5 | 11 | 12 | 16,5 | 21/19* | 26/25* | 27 | 28 | |

* - Depends on design

Table 2. TIREX-PP Composite Plug Technical Characteristics

| Parameter | Value | View | ||||||

|---|---|---|---|---|---|---|---|---|

| TIREX- 82ПП | TIREX- 92ПП | TIREX- 102ПП | TIREX- 110ПП | TIREX- 118ПП | TIREX- 135ПП | TIREX- 146ПП | ||

| Outside diameter, mm | 82 | 92 | 102 | 110 | 118 | 136 | 146 |  |

| Internal casing diameter, mm: | ||||||||

| min | 88 | 98 | 109 | 117 | 125 | 144 | 154 | |

| max | 98 | 109 | 118 | 124 | 133 | 152 | 164 | |

| Adapter sub name | A-KP(AS)-82 | A-KP(AS)-92 | A-KP(AS)-102 | A-KP(AS)-110 | A-KP(AS)-118 | A-KP(AS)-135 | A-KP(AS)-146 | |

| Se ng tool name | PVSh-82PP.300, PVSh-82PP.300FL, IGP-76 | PVSh-102PP.300, PVSh-102PP.300FL, IGP-98 | ||||||

| Max allowable operating temperature, °C | 150 | |||||||

| Max allowable pressure difference between separated intervals, MPa | 70 | |||||||

| Length, mm | 668 | 575 | 633 | 822 | 830 | 840 | 870 | |

| Weight, kg | 2,9 | 3,1 | 4,2 | 6,4 | 7,5 | 10 | 12 | |

Table 3. PVSh-PP-C.400 Plug Technical Characteristics

| Parameter | Value | View | ||||||

|---|---|---|---|---|---|---|---|---|

| PVSh- 97PP-C.400 | PVSh- 102PP-C.400 | PVSh- 110PP-C.400 | PVSh- 118PP-C.400 | PVSh- 135PP-C.400 | PVSh- 138PP-C.400 | PVSh- 146PP-C.400 | ||

| Outside diameter, mm | 97 | 102 | 110 | 118 | 135 | 138 | 146 |  |

| Se ng tool name |

PVSh-82PP.300 IGP-76 |

PVSh-102PP.300 IGP-98 |

||||||

| Internal casing diameter, mm: | ||||||||

| min | 104 | 109 | 117 | 125 | 144 | 146 | 154 | |

| max | 109 | 118 | 124 | 133 | 152 | 155 | 164 | |

| Max allowable operating temperature, °C | 170 | |||||||

| Max allowable pressure difference between separated intervals, MPa | – | |||||||

| Nipple channel diameter for slurry injection, mm | 15 | 20 | ||||||

| Allowable axial load, ts, not more | 20 | |||||||

| Max squeezing pressure, MPa | 50 | |||||||

| Length, mm | 716 | 710/718* | 817 | |||||

| Weight, kg | 11,5 | 13 | 20 | 30/23* | 40/29* | 29 | 31 | |

| Nipple thread type | Thread 73 GOST 633-80 | Thread 73 GOST 633-80 | ||||||

* - Depends on design

Table 4. Technical Characteristics of VrP Series Bridge

| Parameter | Value | View | ||||||

|---|---|---|---|---|---|---|---|---|

| VrP-82 | VrP-92 | VrP-102 | VrP-110 | VrP-118 | VrP-138 | VrP-148 | ||

| Outside diameter, mm | 82 | 92 | 102 | 110 | 118 | 138 | 146 |  |

| Inside diameter of casing, mm : | ||||||||

| minimum | 88 | 99 | 107 | 117 | 128 | 144 | 156 | |

| maximum | 95 | 105 | 115 | 124 | 135 | 154 | 163 | |

| Length, mm | 182 | 182 | 188 | 196 | 200 | 205 | 205 | |

| Weight, kg | 2,4 | 2,5 | 2,6 | 2,7 | 2,8 | 3,0 | 3,1 | |

| Maximum allowable temperature, °С | 100 | |||||||

| Maximum pressure drop between isolated intervals, above the bridge, MPa | 40 | |||||||

| Maximum pressure drop between isolated intervals, under the bridge, MPa | 10* | |||||||

| Setting tool type |

PVSh-82PP.300 IGP-76 |

PVSh-102PP.300 IGP-98 |

||||||

| Working medium | Clay mud, formation water, oil, slurry | |||||||

* - to cut off an interval with high reservoir pressure it is required to cement the bridge

Table 5. PVSh-PP.300 Setting Tool Technical Characteristics

* - Depends on design

Table 6. IGP Hydraulic Seng Tool Technical Characteriscs

* Depends on the assembly opon.