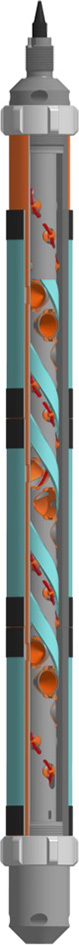

AKV "Plast-S"* combined effect units combine tradional casing perforaon by shaped charges and propellant smulaon by combuson products of propellant charges. The technology of combined effect allows to make a network of addional micro-fissures in the well bore zone increasing perforaon efficiency and well producon rate. AKV "Plast-S" combined effect unit is designed for formaon compleon in cased and liquid-filled oil and gas wells.

The unit is a hollow-carrier expendable jet perforang gun used with shaped charges and propellant charges: external and internal. For safe and reliable operaon of AKV "Plast-S" as well as for reducing peak loads it is required to use damping devices: NKPU.PP-65 cable head for wireline operaons; AT-73PP and AT-102PP vercal shock-absorbers for TCP operaons.

At downhole pressure kick aer firing shaped charges and external and internal propellant charges, the liquid-gas mixture is injected in the formaon with high speed and under high pressure through perforaon channels and natural cracks serving as a wedge forcing apart the rock formaon. The liquid-gas mixture allows to provide downhole pressure higher than total rock pressure. Residual deformaon of the rock formaon prevents healing aer pressure release.

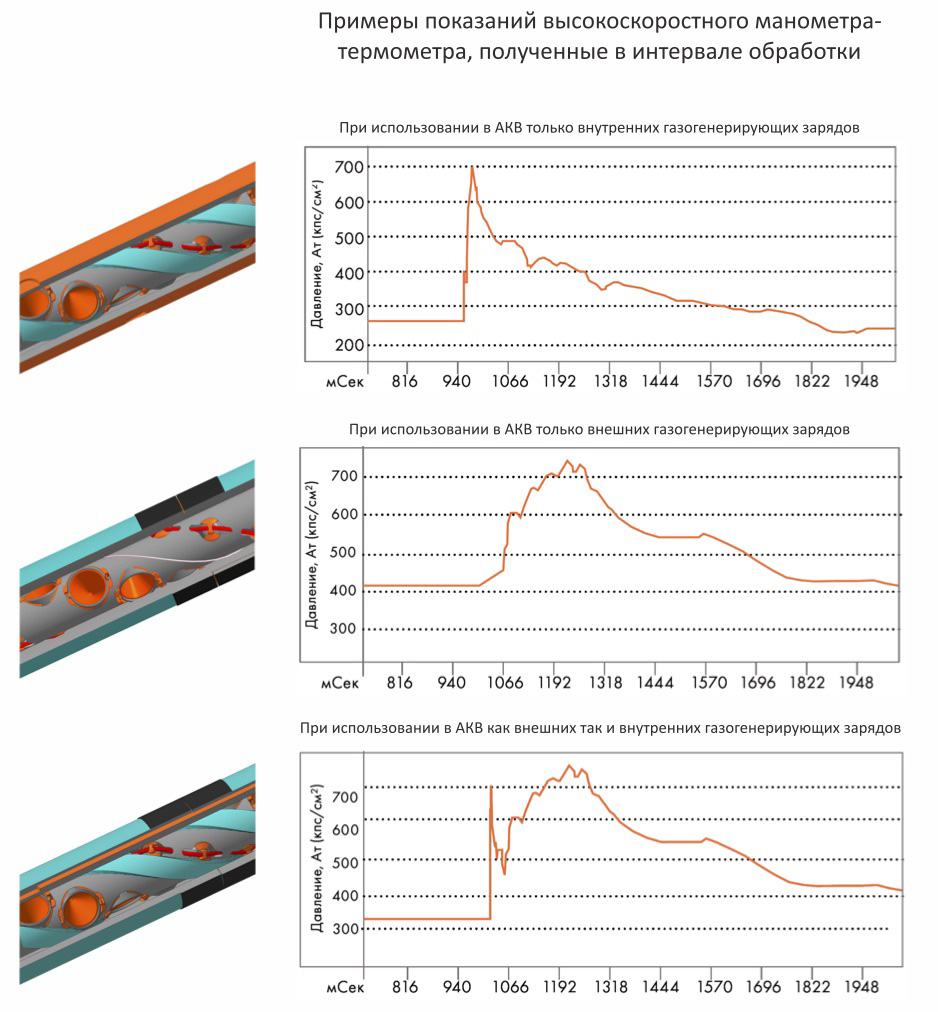

To achieve maximum efficiency while using the combined effect unit there has been developed a special soware "Plast" simulang impact processes in the near well bore area. On the basis of data sheets, LLC "Promperforator" specialists calculate opmal unit arrangement, required number of shaped and propellant charges and make downhole pressure/me diagram. Calculated parameters are analyzed and compared with actual data recorded by a stand-alone high-speed pressure and temperature gauge.

* Protected by the patent №2637267 RF.

Specific Features

- Combuson of internal propellant charges makes a network of cracks filled with acve combuson products; combuson of external propellant charges smulates propagaon of newly formed macro-cracks;

- Two-stage propellant smulaon of the reservoir;

- Mechanical smulaon means making residual well fractures without closing, cleaning of the well zone from chemical reacon products and sand-clay parcles.

- Physical-and-chemical smulaon with combuson products results in dissoluon of carbonate rock and cement as well as in reducon of oil viscosity and surface tension at the boundary with water and rock.

- Heat smulaon results in melng of paraffin deposits and asphalt-resin materials as well as in viscosity reducon due to high temperature at the moment of burning of a propellant charge.

- The unit is also used for prefracturing to decrease inial proppant injecon pressure and to avoid "stops".

AKV "Plast-S" has a convenonal tube design similar to Scorpion series manufactured by LLC "Promperforator" where internal strip propellant charges are located on the loading tube between shaped charges to provide maximum shot density without the loss of mass of propellant charges.

AKV "Plast-S" Technical Characteriscs

| Parameter | Value | |||

|---|---|---|---|---|

| AKV name | «Plast-88S» | «Plast-102S» | «Plast-113S» | «Plast-131S» |

| Max allowable operang temperature, 2 hours hold me, °C | 150 | |||

| Max allowable hydrostac pressure, MPa | 80-140* | |||

| Min allowable hydrostac pressure, MPa | 5 | |||

| Outside diameter/min AKV dri diameter, mm: | ||||

| full package (two pressure pulses) | 88/98 | 102/112 | 113/123 | 131/141 |

| only with internal propellant charges | 64/79 | 73/88 | 89/106 | 102/119 |

| Propellant charges: | ||||

| internal | LGD | LGD | LGD | LGD |

| external | ShNGD-64PP | ShNGD-73PP | ShNGD-89PP | ShNGD-89PP |

| Propellant charge weight: | ||||

| internal | 100±5 | 100±5 | 100±5 | 100±5 |

| external | 780±100 | 1600±100 | 1540±100 | 2100±100 |

| Specific volume of gaseous combuson products of internal/external charges, not less, l | 70/546 | 70/1141 | 70/1008 | 70/1526 |

| Shaped charges |

Scorpion PP-15GP, Scorpion PP-15BO |

Scorpion PP-20GP, Scorpion PP-20SGP, Scorpion PP-30BO, Scorpion PP-20SBO |

Scorpion PP-25GP, Scorpion PP25SGP, Scorpion PP25BO, Scorpion PP25SBO, Scorpion PP25OP |

Scorpion PP-32GP, Scorpion PP-32SGP, Scorpion PP-32OP, Scorpion PP-32SBO, Scorpion PP-36SGP, Scorpion PP-36OP |

| Shaped charge phasing orientaon, degree | 60 | |||

| Carrier length, m | 1/2/3/4/5/6 | |||

* Max allowable pressure can change depending on the mechanical properes of carrier tubes

Charge Characteriscs

| AKV name | Charge name | Charge type | Explosive weight per charge, g | Max shot density, shot/m, phasing, degree | Average parameters of charge penetrang force, QC combined target, mm | |

|---|---|---|---|---|---|---|

| Perforaon depth | Casing hole diameter | |||||

| Plast-88S | Scorpion PP-15GP | DP | 15 |

20/60, 18/60, 16/60, 13/60, 10/60 |

700 | 8,5 |

| Scorpion PP-15BO | BH | 350 | 15,5 | |||

| Plast-102S | Scorpion PP-20GP | DP | 20 |

20/60, 18/60, 16/60, 13/60, 10/60 |

750 | 11 |

| Scorpion PP-20SGP | SDP | 950 | 10 | |||

| Scorpion PP-20BO | BH | 380 | 17,5 | |||

| Scorpion PP-20SBO | SBH | 210 | 21,5 | |||

| Plast-113S | Scorpion PP-25GP | DP | 25 |

20/60, 18/60, 16/60, 13/60, 10/60 |

1000 | 11 |

| Scorpion PP-25SGP | SDP | 1200 | 10 | |||

| Scorpion PP-25BO | BH | 600 | 20 | |||

| Scorpion PP-25SBO | SBH | 250 | 23 | |||

| Scorpion PP-25OP | GH | 600 | 16 | |||

| Plast-131S | Scorpion PP-32GP | DP | 32 |

20/60, 18/60, 16/60, 13/60, 10/60 |

1100 | 11 |

| Scorpion PP-32SGP | SDP | 1300 | 10 | |||

| Scorpion PP-32OP | GH | 700 | 17 | |||

| Scorpion PP-32SBO | SBH | 210 | 25 | |||

| Scorpion PP-36SGP | SDP | 36 |

16/60, 13/60, 10/60 |

1600 | 12 | |

| Scorpion PP-36OP | GH | 1000 | 15 | |||